Teaching Robots to Build: Our Latest Research on Automated Assembly

A look into our new approach for automating construction with self-interlocking blocks and robotic arms.

I’m excited to share some of our latest research on a topic that I find fascinating: automating construction. While we’ve seen robots automate many repetitive tasks in factories, the world of construction has remained largely manual. This is due to the complexity and precision required in building stable structures. In our recent work, we’ve been exploring a new approach to tackle this challenge. You can find the full report here.

The Building Blocks of Automation

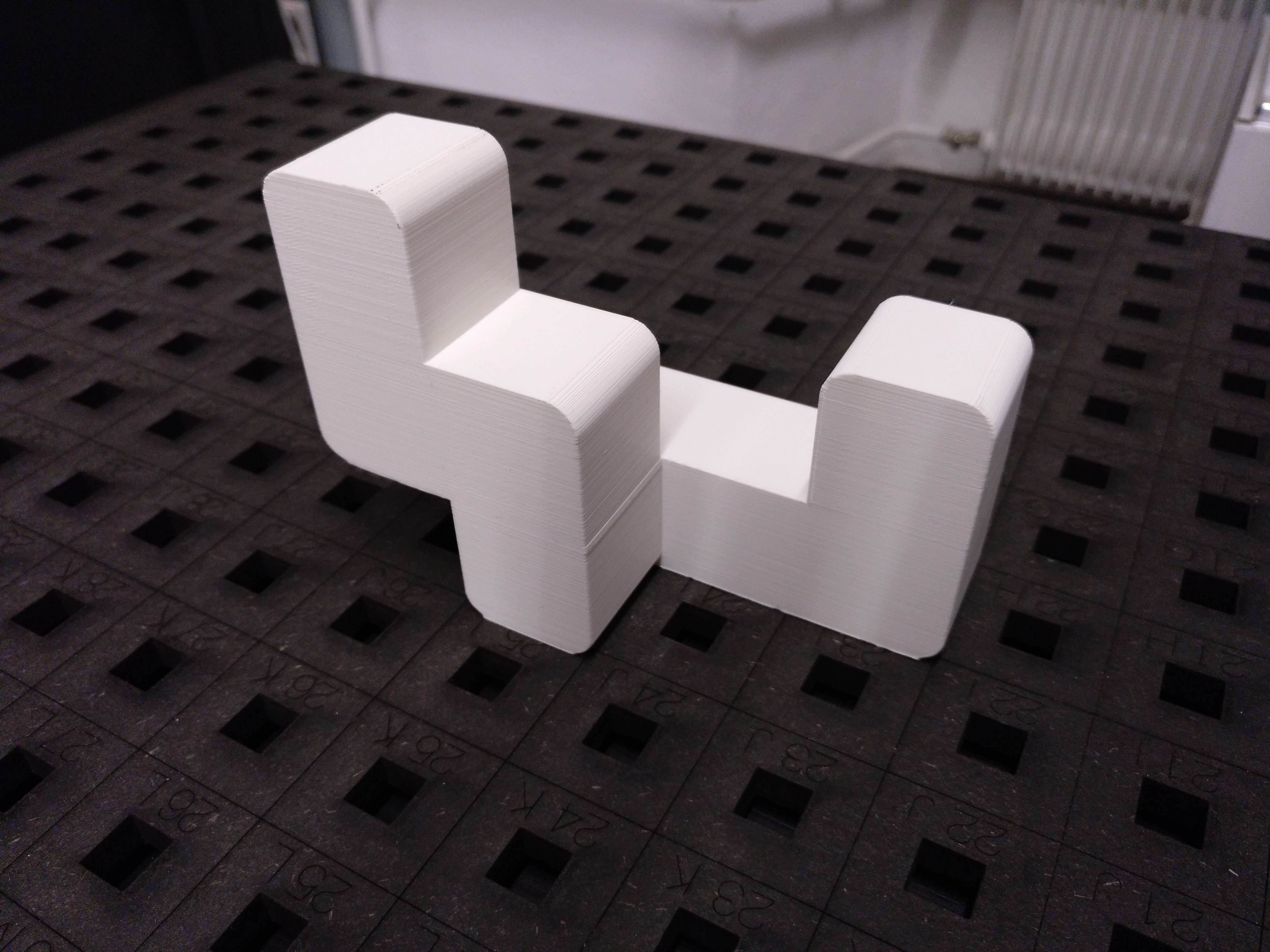

Our research centers around the idea of using a special type of building block, called an SL-Block, which is designed to be self-interlocking. This means that structures can be assembled without the need for mortar or other adhesives, making them not only easier to assemble and disassemble but also more sustainable.

The main goal is to teach a robotic arm to pick up these blocks and place them in the correct sequence to build a predefined structure. This might sound simple, but it comes with a unique set of challenges.

Seeing is Believing: High-Precision Tracking

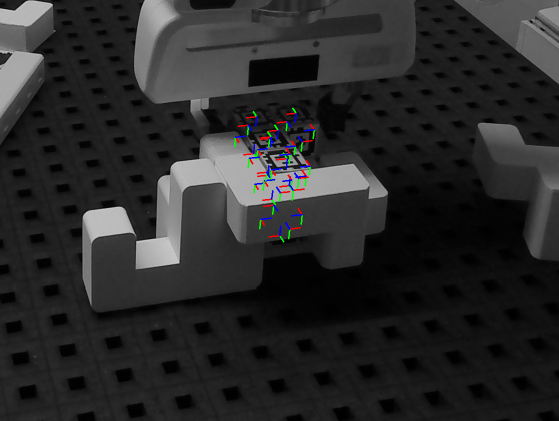

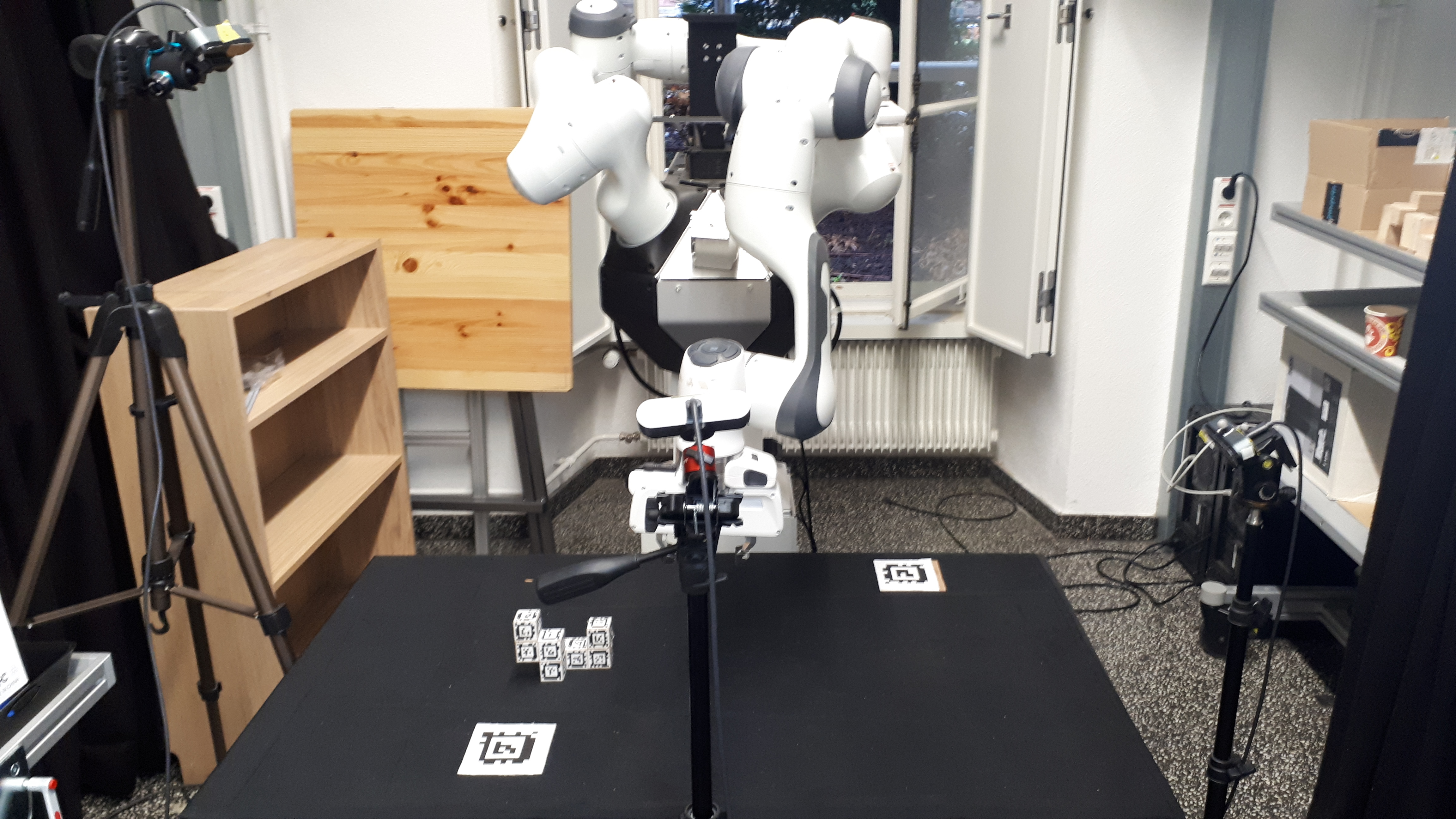

One of the biggest hurdles is ensuring the robot can “see” and handle the blocks with extreme precision. We’re talking about millimeter-level accuracy to ensure the blocks interlock correctly. To achieve this, we’ve equipped each face of the SL-Blocks with fiducial markers, specifically AprilTags. These are like QR codes that our multi-camera setup can easily detect and use to determine the exact position and orientation of each block.

A Gentle Touch: The Importance of Impedance Control

Even with high-precision tracking, the real world is never perfect. To account for small uncertainties and prevent the robot from damaging the blocks (or itself), we use a technique called impedance control. This allows the robot to have a “soft touch,” making it compliant and able to adjust to slight misalignments during the assembly process. It’s like the robot can “feel” its way into placing the block correctly.

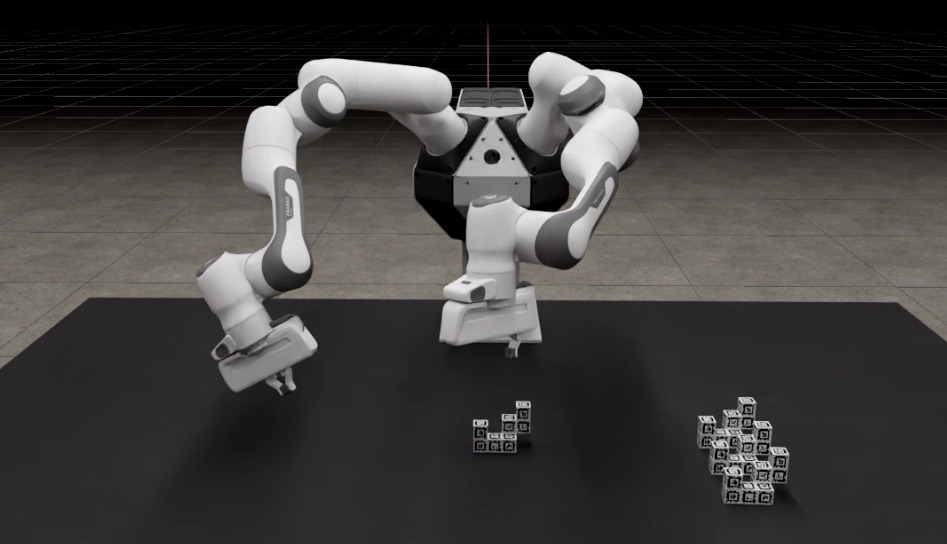

Practice Makes Perfect: The Role of Simulation

Before we let our robot loose on real blocks, we test everything in a simulated environment. We’ve created a digital twin of our entire setup, which allows us to experiment with new ideas, test our tracking algorithms, and refine our control strategies without any real-world consequences. This not only speeds up our development process but also ensures the safety of our hardware.

What’s Next?

Our work so far has been a proof of concept, demonstrating that our approach is viable. We’ve successfully integrated the hardware and software components, and our tracking system can accurately determine the pose of the SL-Blocks. The next exciting step is to integrate this with pre-generated construction plans, allowing the robot to build more complex structures autonomously.

This research has been a great learning experience, and I’m excited to see where it takes us. The idea of robots one day helping us build more sustainable and complex structures is a future I’m eager to be a part of.